In the ever-evolving world of technology, 3D printers have emerged as a groundbreaking innovation—changing the way we design, build, and create. Whether you’re an engineer, student, designer, or small business owner, understanding what a 3D printer is and how it works.

What is a 3D Printer?

A 3D printer is a machine that builds three-dimensional objects layer by layer using a digital file as a blueprint. Unlike traditional printing, which lays ink on paper, 3D printing creates real, physical objects using materials like plastic, resin, metal, or even food.

This revolutionary technology is known as additive manufacturing—where material is added rather than subtracted.

How Does a 3D Printer Work?

The process starts with a 3D model created using CAD (Computer-Aided Design) software. The 3D printer then reads this file and builds the object layer by layer, turning virtual designs into real-world items.

Basic Steps of 3D Printing:

- Design the 3D model (via CAD software)

- Slice the model into printable layers using slicing software

- Load the file into the 3D printer

- Print the object using material like PLA, ABS, or resin

The printer’s nozzle or laser melts or cures the material, building the object from the bottom up, layer after layer.

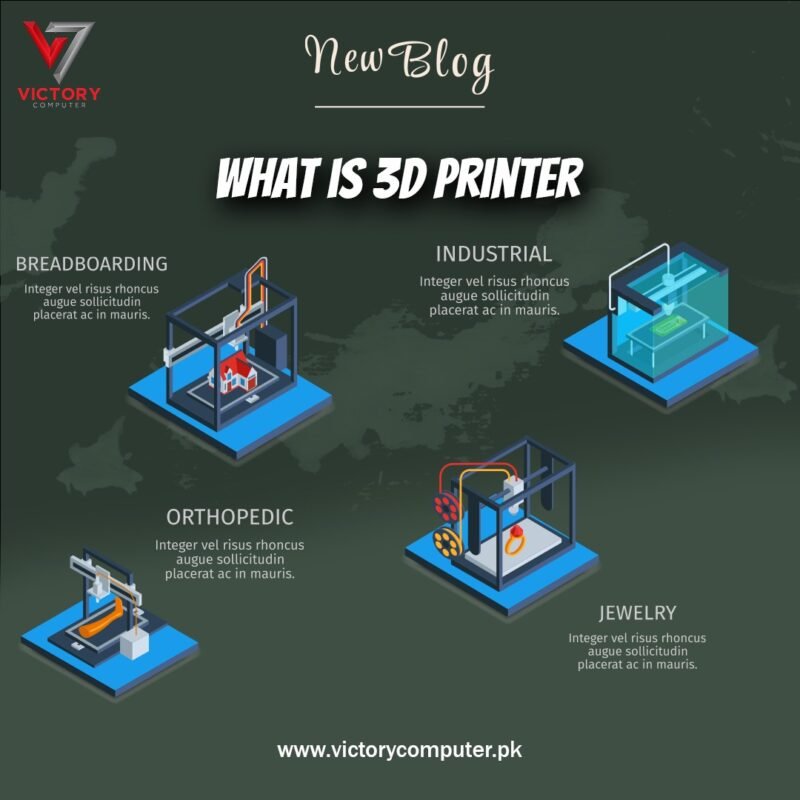

Types of 3D Printers

Different 3D printers use different technologies. The most common types include:

1. FDM (Fused Deposition Modeling)

- Uses thermoplastic filament

- Best for affordable prototyping

- Common in schools and hobbyist setups

2. SLA (Stereolithography)

- Uses resin cured by UV light

- Ideal for detailed, high-resolution printing

3. SLS (Selective Laser Sintering)

- Uses powdered material fused by a laser

- Great for functional parts and industrial use

Impact of 3D Printing

Environmental Problems

Many challenges are faced by our planet, and most of them are related to environmental issues. Now this method can add to these concerns. While 3D prints are very innovative, they lack efficiency in using energy. The procedure of this goes through pre-heating which moves on to printing. Then there are the phases of cooling and each of the phases consumes significant energy.

Just like the traditional manufacturing procedures, this one also ends up emitting a lot of pollutants, and these are caused by the higher energy demands as compared to the standard methods. Also, advancements in this technology could end up mitigating the environmental impacts by reducing the time to print and utilizing low-temperature materials.

Controversy Surrounding 3D-Printed Guns

As mentioned above, there are raised concerns regarding the creation of unregulated firearms due to the accessibility of blueprints and the lack of serial numbers. Now, with this machine, the tracking and regulation of the 3D printed weapons is going to end up posing many difficulties and hence the reliability will be quite questionable.

Drug Production

As you may already know, this also offers the potential for home-based drug production, which will end up raising concerns about regulation and safety. While the promise for medical innovation will remain steadfast, the misuse of drug printing technology poses risks, and this also includes the proliferation of dangerous substances.

Intellectual Property Issues

Nowadays, Intellectual property (IP) infringement is a growing concern in 3D printing, which is reminiscent of digital piracy. The lack of regulation is going to enable the black markets to thrive, which will undermine the rights of IP holders and complicate legal enforcement.

Safety of Food Contact Items

Now, for those who don’t know, the use of ABS plastic in this also raises safety concerns for items in contact with food. This is because the bacteria can thrive on improperly cleaned 3D printers, posing risks when printing kitchenware.

Risks of Property Damage

There can be defective products produced by these machines which may end up causing property damage, leading to legal liabilities for manufacturers.

Potential for Bodily Harm

If faulty products are being created by these printers, it may result in accidents and injuries. This will place the responsibility on manufacturers for inadequate warnings or instructions.

Cybersecurity Threats

Cybercriminals can easily end up exploiting vulnerabilities in 3D printing systems to steal blueprints or produce counterfeit goods.

Health and Safety

Melting plastic during printing ends up emitting substances that can potentially be harmful. This requires precautions such as proper ventilation and material selection. Adherence to safety standards and reliance on professional printing services can minimize health hazards associated with 3D printing.

Due to fluctuation in dollar/dirham rates, prices are not stable kindly confirm the price before placing the order.

Due to fluctuation in dollar/dirham rates, prices are not stable kindly confirm the price before placing the order.